In the world of computer-aided design, SOLIDWORKS assembly modeling stands out as a powerful tool for creating intricate assemblies.

Whether you’re designing complex machinery or elegant consumer products, mastering SOLIDWORKS can significantly enhance your productivity and efficiency. However, to truly unlock its potential, it’s essential to follow best practices for modeling assemblies. In this blog post, we’ll explore some key tips and techniques to help you streamline your assembly modeling process and achieve optimal results.

Plan Your Assembly Structure

Before diving into modeling, take some time to plan the structure of your assembly.

A well-organized SOLIDWORKS tree

A well-organized SOLIDWORKS tree

Identify the main components and sub-assemblies and how they relate to each other. This preliminary planning will provide clarity and organization throughout the modeling process.

Utilize Library Feature Parts and Components

SOLIDWORKS offers a vast library of standard parts and components, ranging from nuts and bolts to gears and bearings.

Whenever possible, leverage these pre-built components instead of modeling them from scratch. This not only saves time but also ensures accuracy and consistency across your designs.

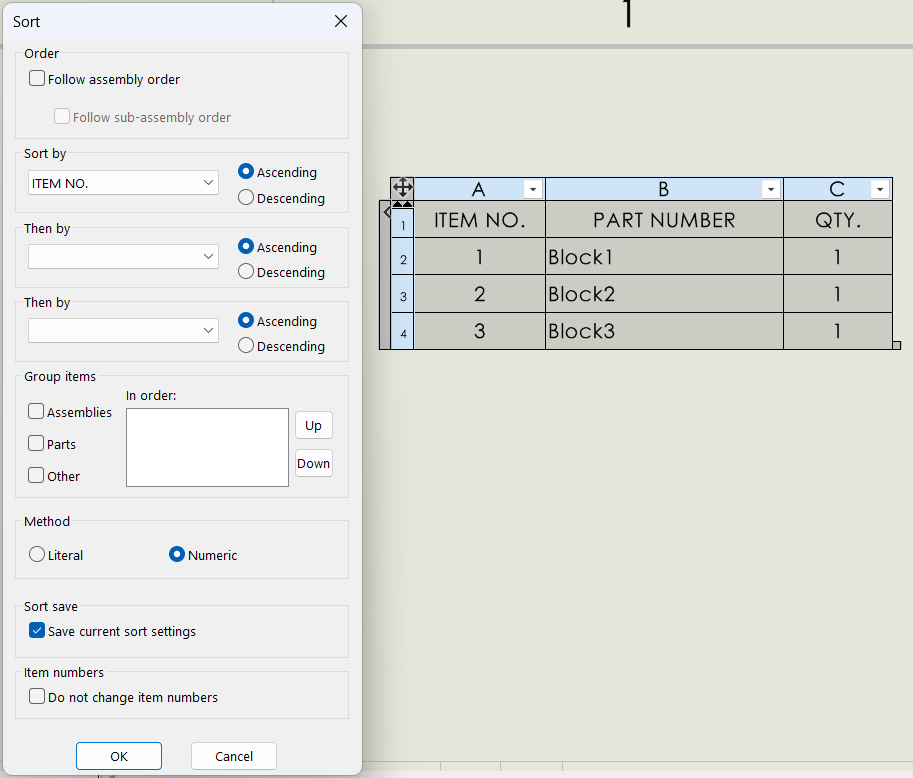

Establish a Naming Convention

Consistent naming conventions for parts and sub-assemblies are essential for maintaining order and clarity in your assembly.

Consistent assembly component naming scheme

Consistent assembly component naming scheme

Establish a naming convention that makes sense for your project and stick to it religiously. This will make it easier to navigate external references and manage large assemblies.

Use Configurations Wisely

Configurations allow you to create multiple variations of a part within the same file.

Using a Design Table for SOLIDWORKS configurations

Using a Design Table for SOLIDWORKS configurations

Harness the power of configurations to model different states or versions of components without cluttering your assembly with redundant parts. This approach helps optimize file size and simplifies assembly management.

Employ Mates Effectively

Mates define the relationships between components in an assembly, such as coincident, concentric, or distance mates.

Effective SOLIDWORKS mates for parent/child relationships

Effective SOLIDWORKS mates for parent/child relationships

Use mates judiciously to constrain parts and ensure they fit together correctly. Avoid over-constraining parts, as this can lead to conflicts and errors in your assembly.

Organize Your Feature Tree

A well-organized feature tree is crucial for maintaining clarity and ease of modification in your assembly.

Group related components and minimize unnecessary sketches and features to keep your tree clean and manageable.

Utilize Assembly Configurations

Similar to part configurations, assembly configurations allow you to create multiple variations of an assembly within the same file.

Use assembly configurations to model different configurations or options of your product without creating separate assembly files.

Optimize Performance

Assemblies can quickly become complex and resource-intensive, impacting system performance.

SOLIDWORKS Large Assembly Settings discussed in training

SOLIDWORKS Large Assembly Settings discussed in training

Take steps to optimize performance by simplifying complex features, suppressing unnecessary components, and using lightweight representations when working with large assemblies.

Document Your Design Intent

Clear documentation is essential for communicating your design intent to others, whether it’s colleagues, manufacturers, or clients.

A SOLIDWORKS exploded view

A SOLIDWORKS exploded view

Use assembly drawings, exploded views, and annotations to provide comprehensive documentation of your assembly.

Continuous Learning and Improvement

SOLIDWORKS is a vast and powerful tool, and there’s always something new to learn.

Stay updated with the latest features and techniques, participate in training courses, and engage with the SOLIDWORKS community to continually improve your skills and knowledge.

How to Learn More SOLIDWORKS Assembly Modeling Best Practices

Mastering SOLIDWORKS assembly modeling requires a combination of planning, organization, and technical skills. By following these best practices and adopting efficient workflows, you can create complex assemblies with confidence and precision, ultimately enhancing your productivity and design capabilities.

These tips are just scratching the surface of what can be done to streamline your assembly modeling in SOLIDWORKS. For more assembly modeling best practices, register for an upcoming training course led by one our our certified instructors.

To view the Assembly Modeling training class schedule, click here.

Cloud Software

law

4

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan